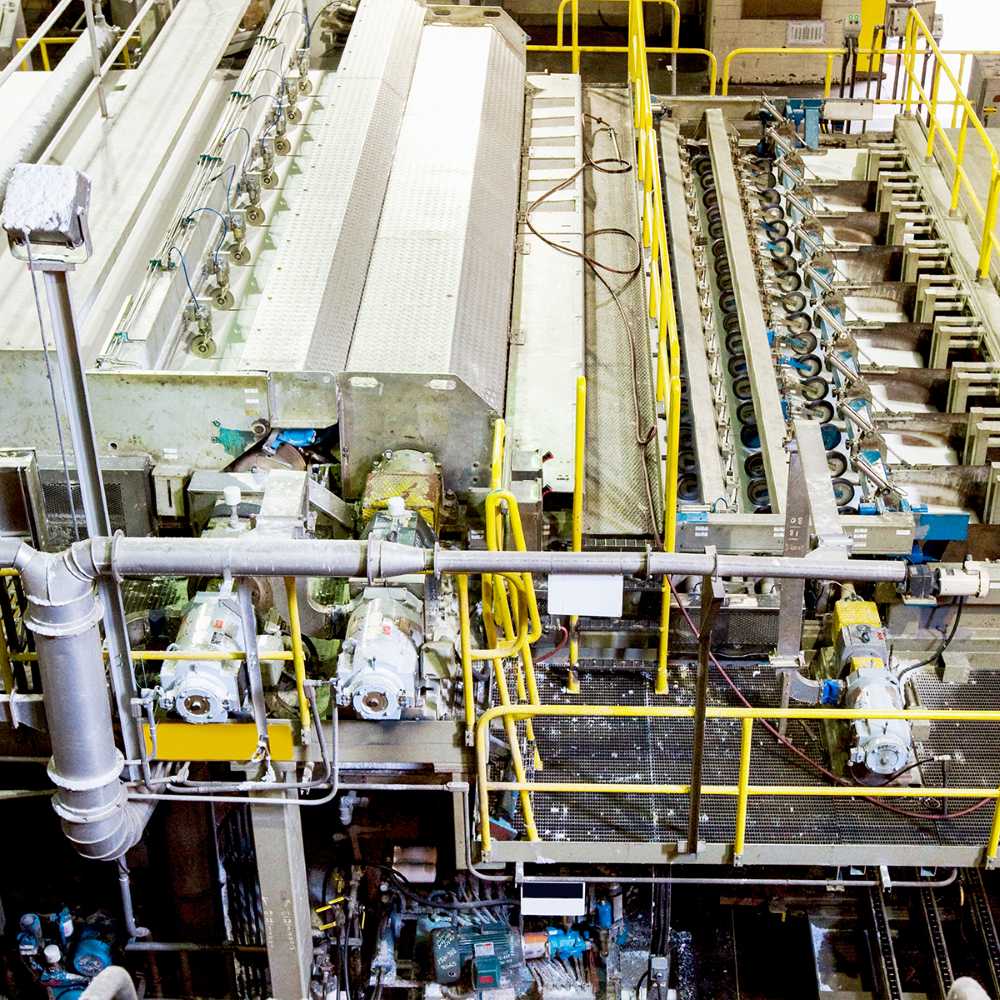

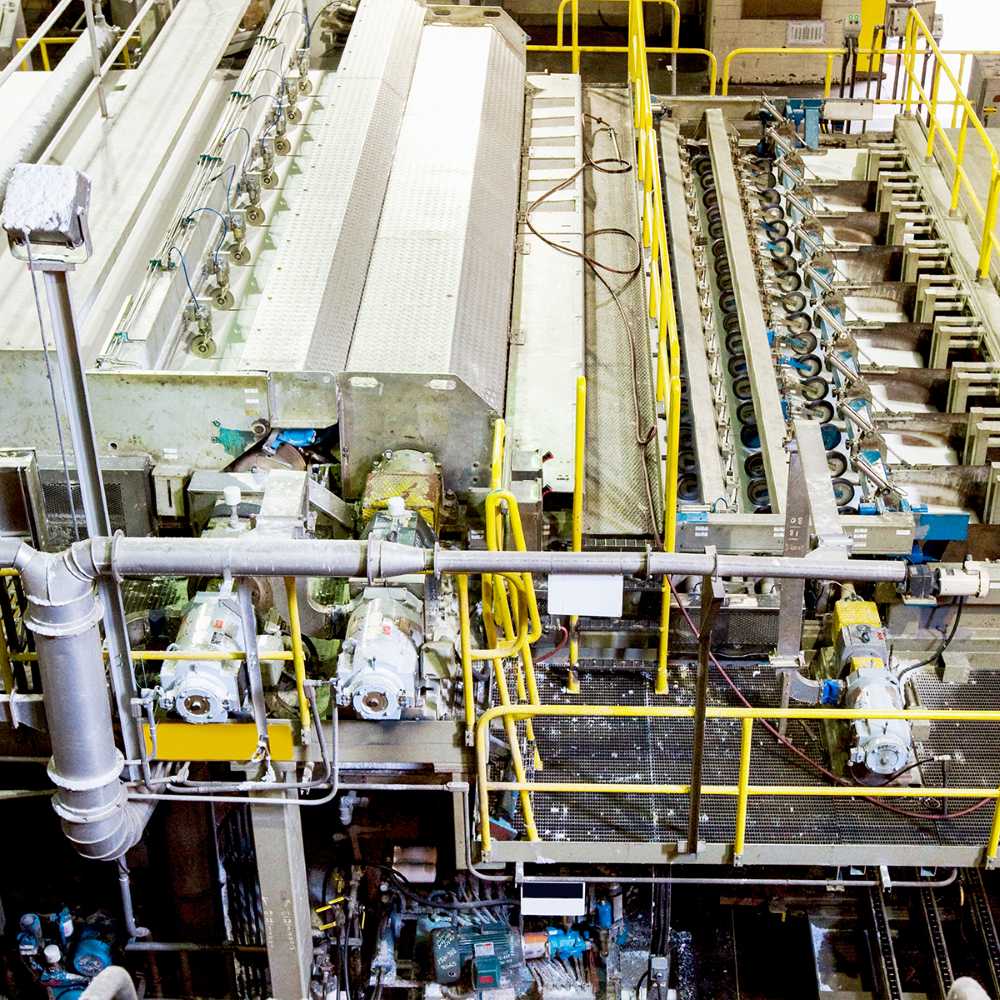

Paper Machine

Keeping your machine running is priority number one. So, when you have planned downtime, you’ve got to make the most of it. You’ll need materials that can be applied while surfaces are still wet. Repairs that can cure under water and gain strength in a few short hours not days. You want the same speed on the dry end. Repairs around the winder, roll conveyors have to cure fast without any residue that could be transferred onto the finished product. Here are a few common applications.

Resurfacing Pits

The pits beneath paper machines in pulp and paper mills are essential to operations but are highly susceptible to wear and damage. Constant exposure to water, chemicals, and heavy machinery vibrations leads to tile loss, coating failures, and concrete deterioration. Over time, these issues can compromise the structural integrity of the pits and disrupt operations.

Regular resurfacing during scheduled maintenance is critical to preserving these vital components. Advanced repair materials that adhere to wet surfaces and can cure underwater are ideal for these challenging environments. These materials allow for effective repairs without requiring extensive downtime, ensuring minimal disruption to production.

Selecting materials that provide durability and chemical resistance is essential for long-term performance. Properly resurfaced pits can better withstand the harsh conditions of pulp and paper production, extending their lifespan and reducing the frequency of repairs. By addressing damage proactively, mills can maintain operational efficiency and protect critical infrastructure.

Related Products

Euclid EucoRepair V100 5 Gallon Pail

$72

Euclid Aquaseal Gel Light Gray 4 Gallon Unit

$341.32

Euclid EucoRepair V100 5 Gallon Pail

$72

Euclid Aquaseal Gel Light Gray 4 Gallon Unit

$341.32

Winder Concrete Repairs & Resurfacing

The winder area in pulp and paper mills endures some of the heaviest mechanical and traffic loads in the facility. Constant movement of machinery, forklifts, and heavy materials causes concrete floors in this area to deteriorate over time. Cracking, spalling, and surface damage are common issues, and if left unaddressed, they can lead to safety risks for workers and interruptions in production.

To keep operations running smoothly, regular concrete repairs and resurfacing are essential. Rapid-setting repair materials are particularly effective for winder areas, as they allow for quick application and minimal downtime. Restoring the surface not only improves safety but also helps maintain the performance and longevity of the area under heavy use.

Things to Consider:

- Surface Preparation: Choose materials that require minimal surface preparation to save time and labor while ensuring a strong bond.

- Curing Time: Fast-curing materials minimize the time needed to reopen the area to traffic, reducing production disruptions.

- Durability: Opt for products designed to withstand the impact and abrasion of heavy machinery and high traffic.

- Worker Training: Proper application techniques are critical to achieving a long-lasting repair. Ensure your maintenance personnel are trained in using the chosen materials.

By addressing concrete damage early and using the right materials and methods, mills can reduce maintenance costs, enhance worker safety, and minimize downtime in this critical area.

Related Products

Euclid Versaspeed 100 50lb Bag

$23.08

Euclid Euco QWIKstitch 21.2oz Dual Cartridge

$63.35

Euclid Versaspeed 100 50lb Bag

$23.08

Euclid Euco QWIKstitch 21.2oz Dual Cartridge

$63.35

Non-Slip Coating

Safety is a top priority in pulp and paper mills, especially in areas prone to slippery conditions. Wet-end sections, basements, and zones surrounding equipment like size presses are often wet or contaminated with oils, making them dangerous for workers and machinery. Sloped surfaces in these areas can exacerbate the risk of slips and falls, leading to potential injuries and operational disruptions.

Applying non-slip coatings is a proactive way to reduce these hazards. These coatings are specifically designed to provide traction on surfaces exposed to water, oils, or chemicals. Choosing the right non-slip material is essential. Oil-contaminated areas require coatings that can bond effectively under such conditions, while high-traffic zones may need more durable options to withstand constant use by both foot traffic and heavy machinery.

By using non-slip coatings, pulp and paper mills can significantly enhance workplace safety, comply with industry regulations, and maintain smooth operations.

Related Products

Aquafin Vaportight Coat-SG2 2.2 Gallon Kit

$456.9

Euclid Duralkote 240 Neutral Base 2 Gallon Kit

$289.93

Aquafin Vaportight Coat-SG2 2.2 Gallon Kit

$456.9

Euclid Duralkote 240 Neutral Base 2 Gallon Kit

$289.93